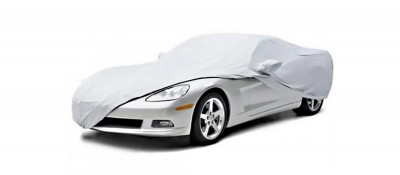

International launch of an innovative FIBC bag at Interpack

Thrace Group joins the leading packaging event with a remarkable innovation for bulk packaging.

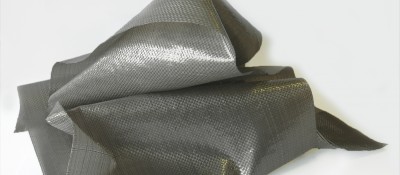

Thrace Polybulk, the Thrace Group expert in big bags, designed and produced a new solution in FIBC with multiple end use benefits. OptiFLOW FIBC bag enhances handling and cost-cutting, by reducing both time and product waste through a set of unique advantages. OptiFLOW’s advantages include:

- Increased capacity due to less inflation time required before filling the bag

- Increased bag stability due to better filled out base

- Improved handling because of reduced filling height / reduced height in stack

- Reduced time for discharging

- Convenience,since the inner-liner stays inside the bag when emptying

- Complete elimination of the lose plastic particles that usually come out when emptying the bag

- 100% performance in bag emptying - no product left inside the bag

- Improved cost savings because of: no product waste / no extra cleaning needs for waste on floor or ground after emptying / no extra work needed to shake the bag for complete emptying

- When discharging at low roof spaces, liner base does not hang outside risking to be covered with discharged product and be ripped off

Thrace Polybulk’s OptiFLOW bag is presented for the very first time at the packaging exhibition of Interpack, which starts today, May the 8th, in Dusseldorf, Germany.