|

Scope

The

project involves the construction of waste treatment plant in Sofia,

Bulgaria.

The US$400 million project includes the following:

1. Construction of 14ha sanitary landfill

2. Construction of a mechanical biological treatment plant with annual

capacity of 410,000 tonnes per annum

3. Construction of a bio waste composting plant

4. Construction of a green waste composting plant with capacity of 24,000

tonnes per annum

5. Construction of a cooling plant

6. Construction of a raw material storage unit

7. Construction of related infrastructural facilities

8. Installation of electricity supply lines

9. Installation of safety systems

|

|

Description

The project involves the construction of a waste treatment plant and is being

implemented in phases.

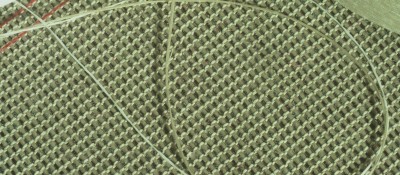

The first phase includes the construction of a 14ha landfill at Sadinata for

non-hazardous bio-waste that has been pre-treated in a Mechanical Biological

Treatment (MBT) plant, it will have capacity of 2,825,000m3. This capacity

will be rolled out in four cells, the first two of which will be able to cope

with 390,000m3 and 515,000m3 of waste, equivalent to 32% of the total

landfill capacity.

It includes the installation of bio-waste treatment facility at Han Bogrov,

which can process 24,000 tonnes per annum of separately collected green waste

and a treatment facility at Han Bogrov for separately collected bio-waste with capacity of 20,000 tonnes per annum.

The second phase includes the construction of an MBT facility with an annual

capacity of 410,000 tonnes.

It includes the construction of a sanitary landfill,a bio-waste composting

plant, a green waste composting plant, a cooling plant and a raw material

storage unit, and installation of mechanical biological treatment, safety

systems and electricity supply lines.

The first phase started operations in 2014 and the second phase Inauguration

was held in September 2015.

|

|

Abstract

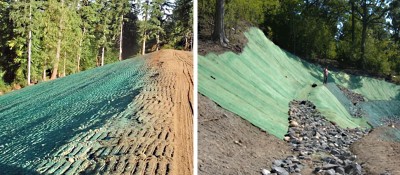

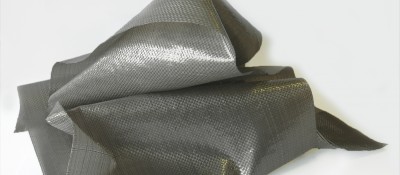

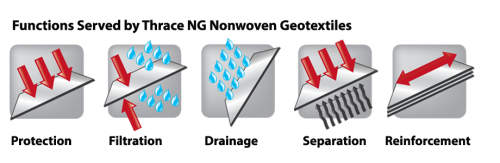

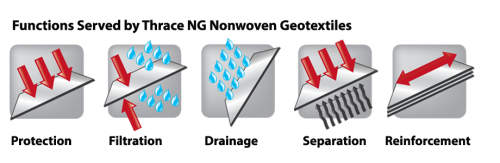

Thrace Group polypropylene nonwoven geotextile P2000NW have been employed in

Sadinata landfill. The function of the P2000NW

nonwoven geotextile was protection from sharp soil surfaces to HDPE geomembrane

liner.

Advantages of

Thrace NG Nonwoven Geotextiles

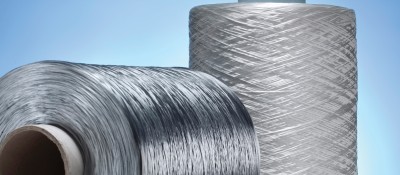

Thrace NG P2000NW nonwoven geotextile is UV stabilized virgin polypropylene, needle

punched. It’s manufactured at one of Thrace NG facilities, with

the latest state-of-the-art fiber

extruders and needle punching lines. Production process is fully vertical

integrated, which guarantees quality

consistency.

Thrace NG nonwoven

geotextile P2000NW offers a high

puncture resistance, wide width of 6m for minimum overlap saving on overlap

wastage.

Project

Owner : Sofia Municipality Contractor: Joint Venture Geotehmin-Unieco

|